In early February 2025, Ultron received a warm inquiry from an Guatemala customer who wanted to purchase a small scale French fries production line to realize his dream of starting a potato chip production venture. Knowing that the customer is a start-up, with limited budget and high requirements for equipment performance and quality, the Ultron team responded quickly, provided customized solutions, successfully won the trust of customers, and successfully delivered the goods in March.

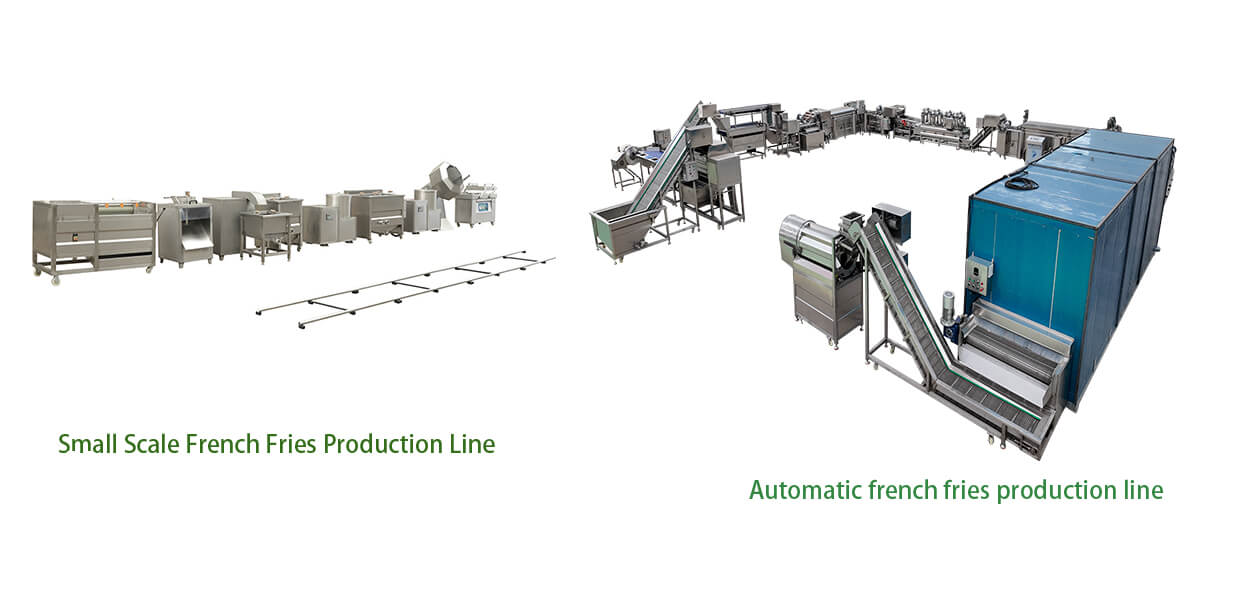

When the customer contacted Ultron, it was clear that this was their first time to set foot in the potato chip processing industry, and they planned to start with small batch production and gradually expand the scale. Considering the actual needs and budget constraints of customers, Gondor’s business team worked closely with technical engineers, repeatedly communicated and optimized the configuration, and finally tailored an economical semi-automatic French fries processing line for customers.

On the premise of ensuring quality and production efficiency, this production line maintains a reasonable cost structure and saves the initial investment pressure for customers.

In order to ensure the reliability of purchasing decisions, customers especially entrust their friends to visit Ultron’s China factory and headquarters office in person. During the visit, our team gave a warm reception, explained the operation principle of key equipment in detail, and demonstrated the main process flow on the spot.

Customers and friends pay special attention to the details of the equipment, from the brand of the motor, the thickness of the stainless steel material of the fuselage, to the hygienic design standard of the contact food parts, all of which have raised professional questions. Our technicians answered them one by one and displayed every manufacturing detail transparently, which enhanced the confidence of customers. Finally, customers spoke highly of the structural design, manufacturing quality, and corporate service attitude of Ultron products, and confirmed the order in late February 2025.

After the customer confirmed the order, Ultron factory quickly started the production plan and strictly followed the internal quality control system. All the equipment has undergone several rounds of debugging and trial operation before leaving the factory to ensure stable and simple operation.

In late March 2025, the equipment completed production and passed the factory test, and the customer confirmed the remote inspection by video. After confirming that the equipment was correct, Ultron arranged export packaging and logistics transportation, and the entire small-scale French fries production line officially set off for Guatemala.

The whole production line is compact in structure, suitable for installation in small processing plants, and equipped with English operation instructions and video guidance to help customers get started quickly.

This cooperation not only confirms Ultron’s professional ability in small food processing line solutions, but also shows our service concept of flexibly matching customer needs and providing customized support. We believe that this potato chip production line will play an important role in the entrepreneurial Guatemala road of customers and become their first step towards success.

We Can Also Provide