Specialized In R&D For Vegetable Washing and Packing line

Capacity :100-300kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel.

Production Name :OEM/ODM Vegetable Washing and Packing Line

All cooperative partners operate well

Specialized In R&D For OEM/ODM vegetable washing and packing line

Capacity :300-500kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel.

Production Name :OEM/ODM vegetable washing and packing line.

All cooperative partners operate well

Specialized In R&D For vegetable washing and packing line

Capacity :500-700kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel.

Production Name :Vegetable washing and packing line .

All cooperative partners operate well.

Specialized In R&D For Vegetable Washing and Packing Line

Capacity :700-900kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel.

Production Name :Vegetable Washing and Packing line

All cooperative partners operate well.

Specialized In R&D For Vegetable washing and packing line

Capacity :900-1200kg/h customzied as your need.

Material :Food Grade 304 Stainless Steel

Production Name :OEM/ODM vegetable washing and packing line

All cooperative partners operate well

Introduce

Production Process

Parameter

Process Display

Characteristic

Advantage

Application

Customer Case

Vegetables are an integral part of the daily diet. Vegetables can be cooked on their own, or combined with meat to create dishes, with fruit to create salads and with pasta to create various types of pasta. Vegetables are widely used, nutritious and delicious, but the pre-processing of vegetables harvested from the land not only has yellow leaves, but also a lot of soil, which inevitably has to be washed several times before processing, which has put many people off. The food processing industry sees a business opportunity in this, with large-scale cleaning and processing lines that can make it possible for thousands of households to buy clean vegetables that can be processed directly. The following is an example of leafy vegetables cabbage, to share vegetable cleaning and packaging line equipment.

|

Item |

Power |

Size |

|

Bubble Washing machine |

3.75kw/380v/50Hz |

4000*1200*1300mm |

|

Hoisting machine |

0.75kw/380v/50Hz |

2000*1000*1900mm |

|

Hair roller cleaning machine |

2.0kw/380v/50Hz |

2000*1000*1300mm |

|

Vibrating machine |

1.5kw/380v/50Hz |

1500*1000*1300mm |

|

Air drying machine |

15kw/380v/50Hz |

4000*1200*1400mm |

|

Packing machine |

12kw/380v/50Hz |

3000*1500*1000mm |

| Note: These parameters are conventional and can be customized according to customer needs | ||

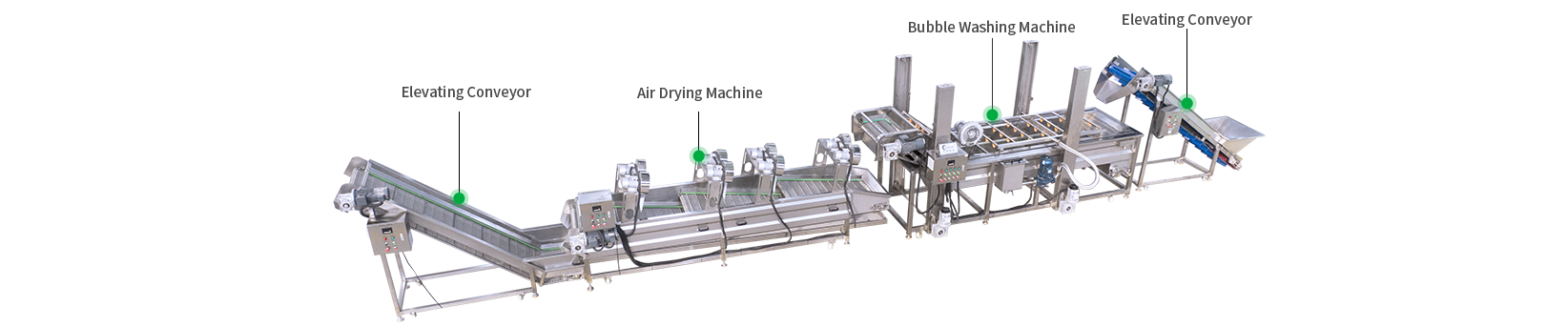

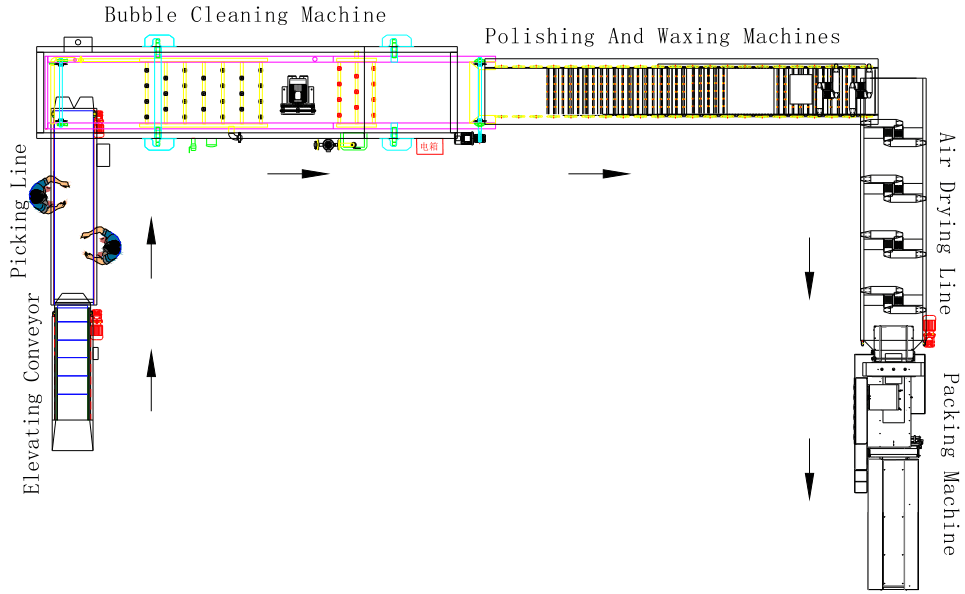

Fruits and vegetable washing and packing line process:

Vegetable washing and packaging line process: cut the root, go to the yellow leaves - cut - two cleaning - transport - -Drying - Lifting - Packaging.

Vegetable washing and packaging line equipment

1. Multi-station picking table Harvested cabbage with roots and yellow leaves. On the multi-station picking table, workers in food overalls manually cut off the cabbage roots, pick out the yellow leaves and place the root-cut cabbage on the conveyor belt.

2. Multifunctional vegetable cutter The cut cabbage is fed into the multi-purpose chopper in turn, which completes the continuous chopping process in accordance with the set chopping standards.

3. Lifting machine The cut vegetables are lifted into the vortex washing machine.

4. Vortex washing machine 2 sets The vortex washer is a flexible washing machine suitable for cleaning cut vegetables, making them clean and avoiding damage to them at the same time. The vortex washer is also equipped with a vibrating draining device. 2 vortex washers allow the vegetables to be washed twice, improving cleanliness.

5. Two-way conveyor belt The cleaned and drained vegetables pass through a two-way conveyor belt into the vegetable basket. The two-way conveyor, with 2 centrifugal driers, doubles the processing efficiency.

6. 2 centrifugal driers The basket is placed in the centrifugal dryer with 85% of the vegetables loaded. The water on the surface of the vegetables is dried by the centrifugal principle. This increases the freshness and shelf life of the vegetables.

7. Lifting machine The dried vegetable strips are poured into the inlet and through the elevator into the packaging, metal detection and labelling process.

8. Shrink wrap packaging machine Fruit and vegetable heat shrink film packaging machine using rapid heating and cooling technology, can complete the packaging process in a short time. Depending on the product, automatic feeding systems are available as an option to achieve unmanned feeding, and various forms of conveyors ensure that the material does not move or roll over. The vegetable washing and packaging line equipment developed and designed by our company will be personalised according to the different characteristics of each vegetable and the customer's processing needs, in order to meet the diverse needs of our customers Fruits And Vegetable Washing and Packing Process:

Process capacity: (finished capacity 100kg/h to 5000kg/h) and work flow can be customized.

High Automation:Fully automated operation from washing to packing, saving labor.

Heating method: Electric heating, Gas heating or Diesel heating , etc.

Size:The capacity of washing and packing line are adjustable.

Designed with flexibility to accommodate processing workshops.We offer customized solutions tailored to your workshop area to optimize your production line equipment layout.

Additionally ,this production line is capable of processing a wide range of potato washing ,particularly specializing in root and tuber vegetable such as potatoes ,carrots ,and beets,cassava .It provides diverse processing capabilities to meet broad market demands.